Follow a manual added link

ABOUT COMPANY

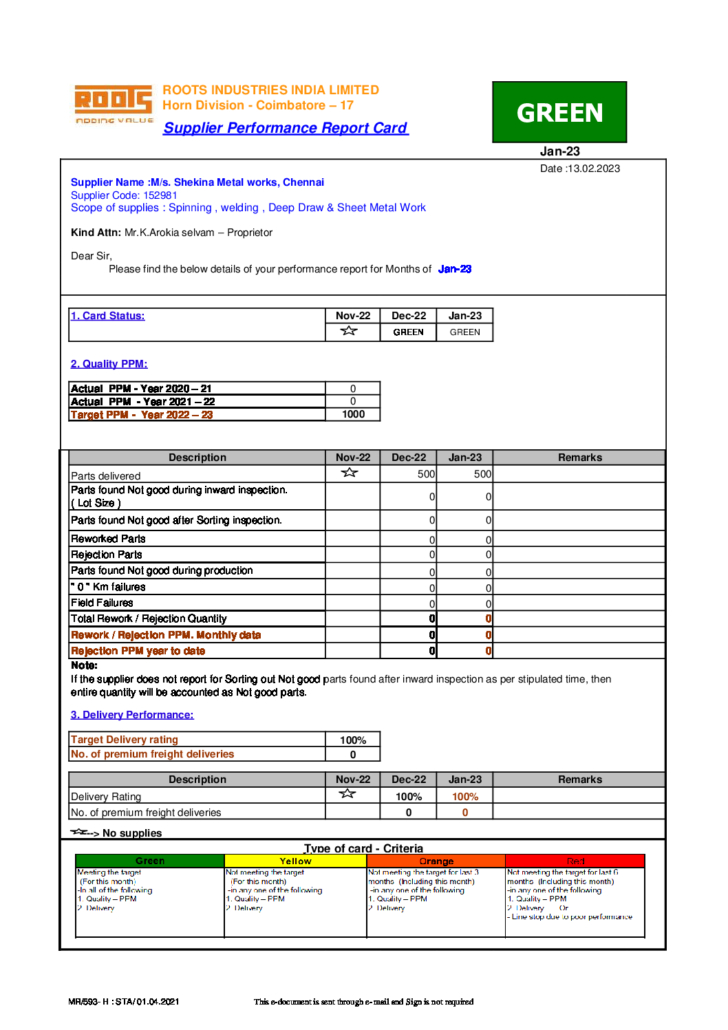

Shekina Metal Works

Introducing ourselves as a best in class service provider for metal Spinning & Deep Drawing Combined with Welding Technology.

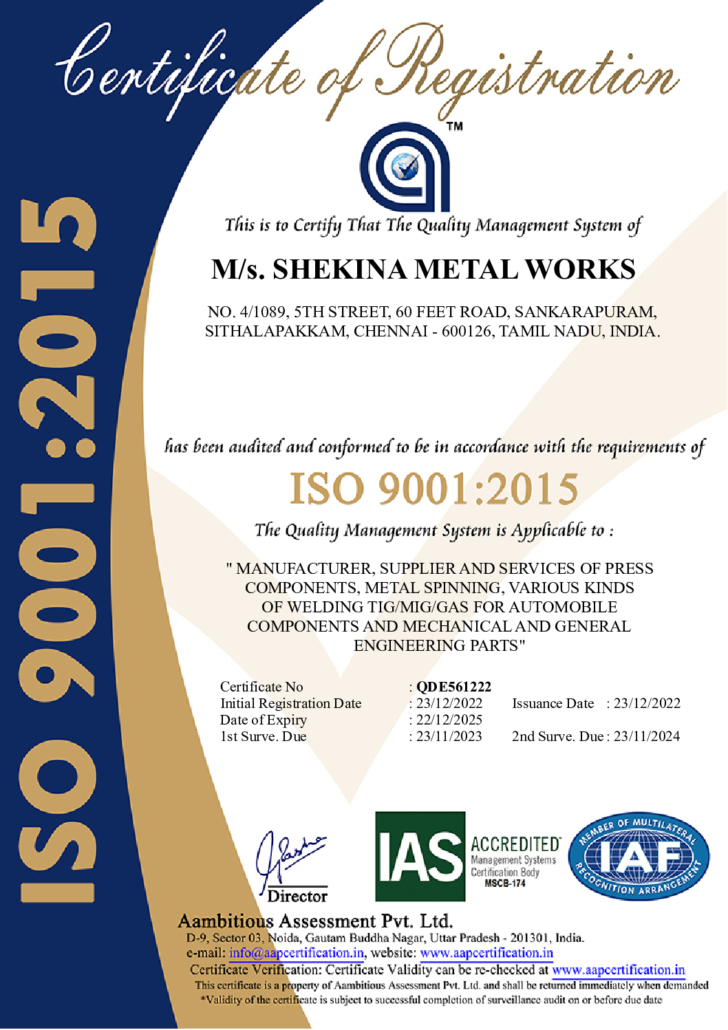

SHEKINA METAL WORKS is a ISO 9001:2015 certified company. We are a major supplier of Metal Spinning Products and refining services to Automobiles, Textiles, Engineering and Home Appliance industries. We are a Small sized business that believes in delighting our Customers with our product quality and Customer Service. We have been working in this field since 1983 at Chennai, Tamilnadu , India.

The Core business of SHEKINA is engineering & producing Sheet metal components by metal Spinning, Flow Forming and Deep drawing combined with Welding technology in Stainless steel, mild steel, Aluminums, Copper and Brass and Specialty steels such as inconel, monel, etc. as per customer drawing and design

Specialization

We are specialized in doing jobs by sophisticated hydraulic spinning system. Our present spinning capacity from Diameter 40mm to 550mm and length of 40mm to 600mm and thickness up to 3mm. We produce various sizes & dimension such as Round, Oval, Square, Radius, cylindrical, Taper and Conical etc. and also the various materials such MS, CRS, HRS, SS, Aluminum , Brass, Copper, Inco alloy, etc to the various industries like Automobile, Home appliances, Textile Parts, Electric & Lighting, Fan Industries, Pharmaceutical & General Engineering.

Production Capacity : 75 TONNES per month.

Top Export Countries : United States of America, Australia, United Kingdom

This includes technical knowhow in Metal Spinning, Deep drawing and Welding process:

- Design & Development of Sheet metal components

- Manufacturing of Metal spinning components

- Combined process of metal spinning and deep drawing with welding techniques.

- Non visible of welding marks on sheet metal surface

- Round/Conical/Tapered/Radius spinning parts

- Process includes Spinning/grooving, Deep Drawing/ /Beading/Flaring/Converging/Swaging/Buffing etc.

- Flow forming/Reducing/Enlarging of tubes, formed ends.

- Rings/Dishes & dished ends/V-Clamps/U – Clamps etc.

- Exhaust assembly parts related to BS-6

- Long cones/short cones/Beaded pipes/Flared pipes Developing and manufacturing fuel cell components.

- Shield Covers/buckets/shells/Hydrolysis Pipes/Inlet Pipes

- Watering cans/Top covers/Cone Hoppers & funnels

- Inner Catalyst Guide/Duct Burner/Top Dishes

- BS VI exhaust components like DOC shells, DPF Shells, Body Mufflers etc…